Artificial Lift & Production Systems (ALPS)

Seaharvest ALS division is a true partner and worldwide supplier of complete Artificial Lift equipment and packaged solutions.

Our expertise collaborate with you to properly evaluate well conditions and provide customized artificial lift solutions that optimize your production.

Seaharvest has a proven experience in supplying, servicing, and consulting activities related to Artificial Lifting Systems, Thanks to our leading vendors that play a withstanding role in the ALS market, and still keeping their worldwide ranks at the lead.

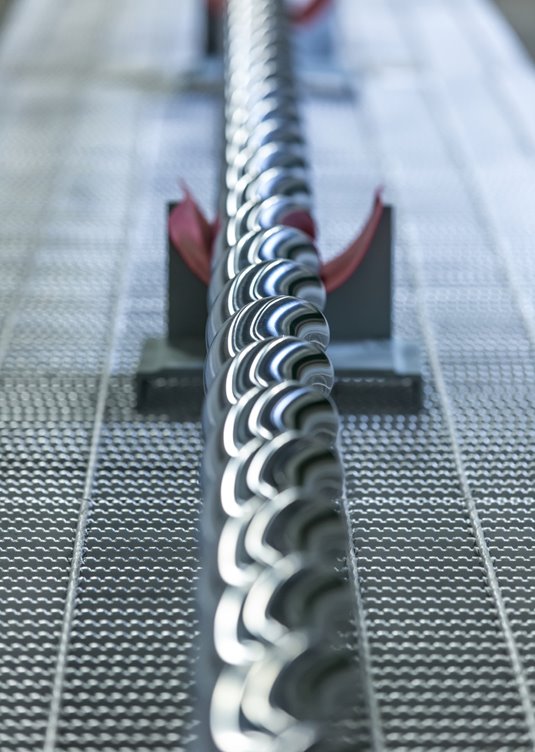

SEAHARVEST provides sucker rods in a fully integrated industrial process to meet the growing demand of our customers in the region. We deliver API sucker rods ranging from 5/8” up to 1-1/2”, with lengths of 25 or 30 feet. We offer also Polished Rods that conform to AISI Steel Products Manual, according to a rigorous quality assurance system that complies with ISO 9001:2000 and API 11-B latest edition.

All steel materials and properties are available which applicable to your applications “Alloy Steel, Chrome, Spray metal, Upset, Stainless Steel” that have high performance, optimize production, reduce production costs and maximize well profitability.

We have the capabilities to supply Steel, Fiber glass or coiled rods; equivalent to

- Ultra High Strength

- High Strength

- Grad D

Polish Rods

- Piston Steel

- 4140 Alloy

- Hard Faced

- 431 Stainless Steel

- N50

Pony Rods: 2, 4, 6, 8, 10 and 12 feet are available for each steel grade and rod body diameter

Sinker Bars: both carbon steel and alloy steel in sizes 1 ½, 1 ¼, 1 ⅝

Stuffing box

Sucker Rod guides

Sucker Rod &Polish Rod Accessories

Fishing Tools (standard over-shots and special ones fabricated for specific cases)

Rod clamps: single, double, and triple Bolt

Sucker rod, polish rod and combination coupling and crossovers (slim hole and full size)

SEAHARVEST provide downhole pumps with a complete line of precision, sand-resistant subsurface oil well pumping equipment and full application services. Our manufacturers have established a remarkable record for performance, dependability, efficiency, and economy. They are registered to API Specification Q1 and ISO 9001:2008, which dictate quality management system components. SEAHARVEST provides all products in accordance with API Specification 11AX.

Seaharvest supplies all different types of both API and/or specialty pumps:

- Tubing Pumps

- Insert pumps

In addition to almost all pumps’ spare parts:

- Barrels

- Plungers

- Valve Cages

- Balls and Seats

Downhole Accessories:

- Pump Anchors

- Tubing Anchor Catchers

- Seating Nipples

- Lift Sub

- Tubing Test Valve

- Gas Separators

- Tubing Anchor Catcher

- Sand Screens

- Downhole injection system

Hydraulic Pumping System:

Our new hydraulic pumping unit is a new surface mounted artificial lift system for sucker rod completion. This technology utilizes electronic and hydraulic equipment and computer monitoring systems for extracting fluids in an extremely efficient manner in non-eruptive wells.

Our unit consists of two main components: the Power Unit and the Hydraulic Cylinder. The Power Unit is the control center of the system and it’s responsible for driving the hydraulic cylinder and the cylinder mounted over the wellhead provides the lifting capacity and determines the stroke length. The available different sized Power Units and cylinders are matched to meet the specifications of each oil well.

Mechanical Linear Pump:

The Compact Sucker-rod Surface Unit

Smart Pump mounts directly to the wellhead. The polished rod runs through a channel inside the rack and is suspended from the top by a conventional rod clamp. The SLRP unit is small, lightweight, and easy to transport. No specialized or heavy equipment is required, which saves on installation costs.

Features

- Variable-speed Control

- Simple Mechanics

- Industry-leading Control Software

- Compact and lightweight

- Simple Design

- Easy To Install

- Advanced Control

- Superior Pump Speed Control

Beam pumps:

SEAHARVEST offers a complete package and full range of pumping equipment, electronics, software, and services for all of your application requirements. We supply a comprehensive range of pumping units that includes all makes and models, spare parts, and knowledgeable staff who quickly locate exactly what you need. We supply either Conventional & Beam-Balanced Pumping unit, Advanced Geometry Pumping Unit or Low-Profile Pumping Unit

Our Beam pumping units are available in sizes from API 80 to 1280

Jet pumps is one of the unique systems that offer a practical solution for wide range of well conditions. Being able to lift oil with API within 15 up to 48, without caring by the associated gases; this equation makes jet pumps one of the systems that should be considered for new ALS projects.

Seaharvest works exclusively with class A manufacturers to bring their technologies and new applications to the region.

- Injection pumps:

- Multiplex pumps ranges from 80 to 400 Hp

- Horizontal Pumping System (HPS)

We provide you with a range of HPS pumps that cover the different operating conditions; different power, no of stages, impeller sizes, and lengths. Any pump we sell is covered by 24/7 technical support to keep your operation going with least interruptions.

- Spare parts for our own brands and also for the other well-known brands (Like NOV Multiplex pumps)

- Complete Vessels Skid with all components:

- Separators

- Cyclones

- Dampeners

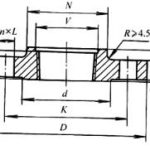

Being one of the leaders to fabricate wellhead spools in Egypt, Seaharvest took a lead in fabricating KTH wellhead flange for Sucker rod operated wells, with a developed design that solves any defects noticed in our competitors’ products, in addition to higher load capacity that’s assured after passing a real tough testing conditions to grant a superior quality that matches with API 6A standard.

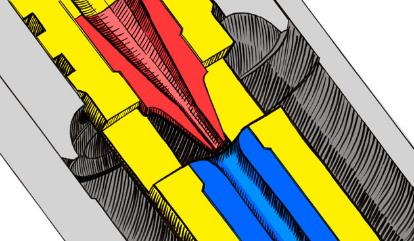

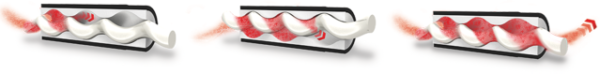

Our name in this part is bonded to big names has a remarkable in PCP market all over the world. We have the capability to supply a full PCP scope; wellhead drives, BOPs, progressing cavity pumps, automation and remote power units.

Our Pumps are designed for effective production under less than ideal conditions, including sandy, heavy oil, depleted wells, and dewatering gas wells.

Each PC Pump is manufactured with precision and application engineering expertise to achieve a proper fit in relation to your application’s unique characteristics. This ensures reliable operation and maximum durability over the life of your equipment.

Also we have our mark in bringing the up-to-date technology all over the world like downhole motorized systems and special designed stators

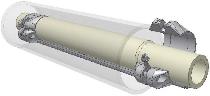

Seaharvest provides Gas Lift Systems of high quality. Our systems can utilize both wireline and tubing retrievable deployment options.

In addition, we have a combination lift system, in which gas lift and hydraulic lift are both used. This system utilizes Jet Lift initially to kick off liquid loaded wells (ex: after Frac jobs) until gas shows up; building lasting production partnerships.

Seaharvest has a complete line of Control line and ESP Cable Protectors

Our protectors features:

- streamlined design;

- rapid installation

- excellent resistance against skidding of the protector on the tubing

- excellent resistance against slippage of the lines and cable in the protector

- excellent prevention from twisting of control line, crushing and also from erosion against the tubing coupling and the casing

- minimum risk of getting stuck while running the tubing in the well

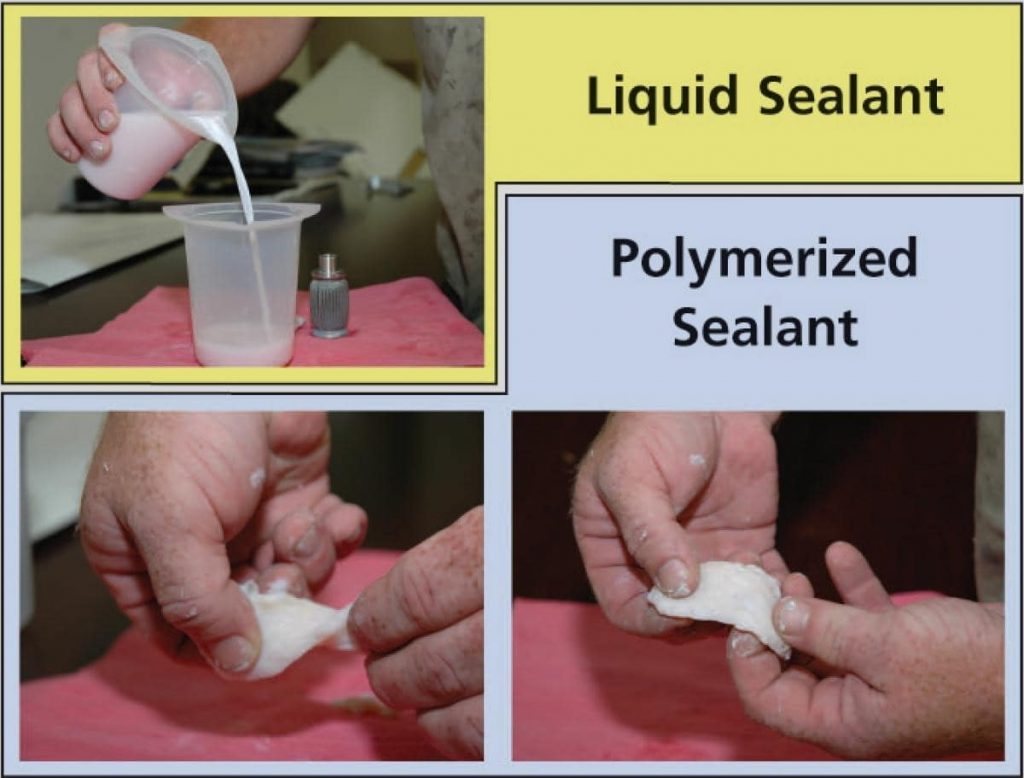

Seal-Tite International has a line of unique pressure-activated sealants that seal leaks in oilfield environments. The sealants are unique in that the pressure drop through the leak site causes the sealants to polymerize into a flexible solid. Only at this point of differential pressure will the sealant polymerization process occur. As the reaction proceeds polymerized sealant forms at the edges of the leak site and simultaneously links together to form a flexible bond across the leak site. The remainder of the sealant is the system remains liquid.

Seal-Tite® International has a line of unique pressure-activated sealants that seal leaks in oilfield environments.

The sealants are unique in that the pressure drop through the leak site causes the sealants to polymerize into a flexible solid. Only at this point of differential pressure will the sealant polymerization process occur. As the reaction proceeds, polymerized sealant forms at the edges of the leak site and simultaneously links together to form a flexible bond across the leak site. The remainder of the sealant in the system remains liquid.

PRESSURE-ACTIVATED SEALANT CHARACTERISTICS

- Liquid sealant

- Pressure activated

- Polymerizes into a flexible solid

- Solidifies only at the leak site

- Excess sealant remains liquid

- Tested to 22,000 psi and 500° F

Our composite pipe systems efficiently transport scarce resources directly to consumers. The non-corrosive characteristic of composites, including fiberglass means they are materials of choice across a wide range of applications in all pressures, temperatures and mediums.

All products are manufactured in accordance with stringent customer specifications and according to the most demanding international standards.

We offer a extensive portfolio of tailored products and solutions which can meet extreme environmental requirements, including the ability to withstand very high pressures of up to 3500 PSI

Down-hole Tubing and Well Casing

Downhole pipes used for water injection, CO2 injection, waste injection and production lines as well as well casings for oil & gas, water and chemical wells.

Seaharvest has a long experience in ALS for both: supplying equipment and applying services. Our crews are well trained and experienced to hold operations 24/7 and to provide service activities in the different techniques of artificial lift.

Our Engineers and operators have a proven experience with a wide range of operators in EGYPT, Adding to this, we have the capacity to do all the operations needed at the field or maintenance needed in workshop Like: pumps teardown, parts replacement, testing and inspection of pumps.